In this hot summer season, our company received a special order from Xinzhou, Shanxi. The customer required to convert the old concrete mixing plant into a stabilized soil mixing plant.

There are significant differences between stabilized soil mixing plants and concrete mixing plants in essence, which also shows that this transformation presents huge challenges.

Step 1: The technical staff of the company’s technical department will conduct on-site inspections and issue feasibility plans and design drawings to make full use of the original equipment parts and save customers unnecessary losses.

Step 2: The production workshop will produce and manufacture the required equipment parts.

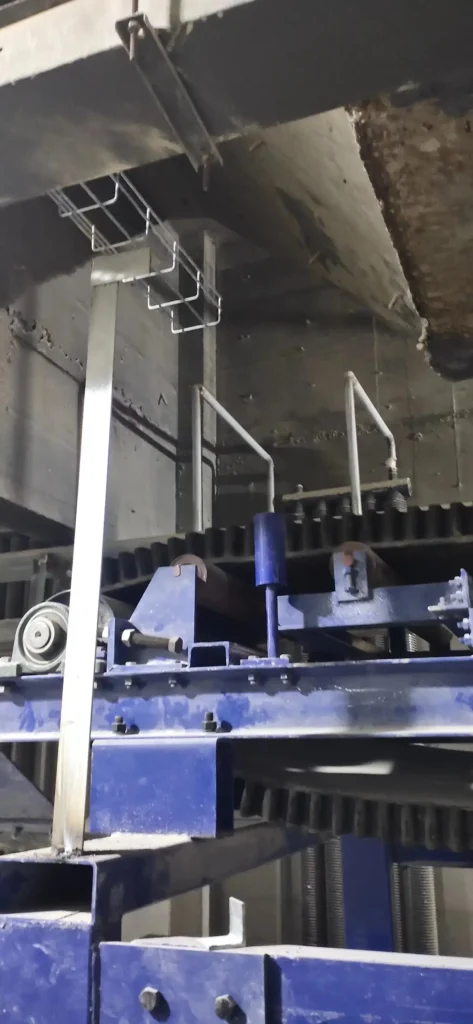

Step 3: The company will send professional installation personnel to conduct on-site surveys and renovation and installation of the site.

The renovation work retained the original cement silo, main building, sand and gravel hopper, etc. The equipment discharge mode was changed from intermittent to continuous, the batching system was changed to a continuous computer belt scale, the mixer was changed from a concrete mixer to a stabilized soil double mixer, and a cement powder transition bin was added, as well as a finished product storage bin.

Our company focuses on the actual needs of customers and transforms equipment according to the actual situation of the site.