- No. 108, Minghu North Road, Anqiu Economic Development Zone, Shandong Province

- marketing@luton-group.com

- +86-156 8919 6666

The HZS90 concrete mixing plant is a fully automatic concrete mixing equipment consisting of batching, mixing, electrical control, and other parts. It is suitable for medium to large-scale construction sites, prefabrication factories, and commercial concrete production plants.

The HZS90 concrete mixing plant is a fully automatic concrete mixing equipment consisting of batching, mixing, electrical control, and other parts. It is suitable for medium to large-scale construction sites, prefabrication factories, and commercial concrete production plants. Its main features are:

Adopting a modular structure, the installation and relocation of the entire machine are very convenient, and the equipment cost is low.

The host adopts LTJS1500 or Shigoma 1500 double horizontal axis forced concrete mixer, which has good mixing quality and high efficiency.

The aggregate is prepared using a PL2400 batching machine, which provides accurate measurement and high production efficiency.

The ingredients of cement, water, and liquid additives are all measured using electronic scales, with high accuracy in ingredient preparation.

The water supply system adopts a water pump to supply water, which accelerates the water flow rate and sprays evenly.

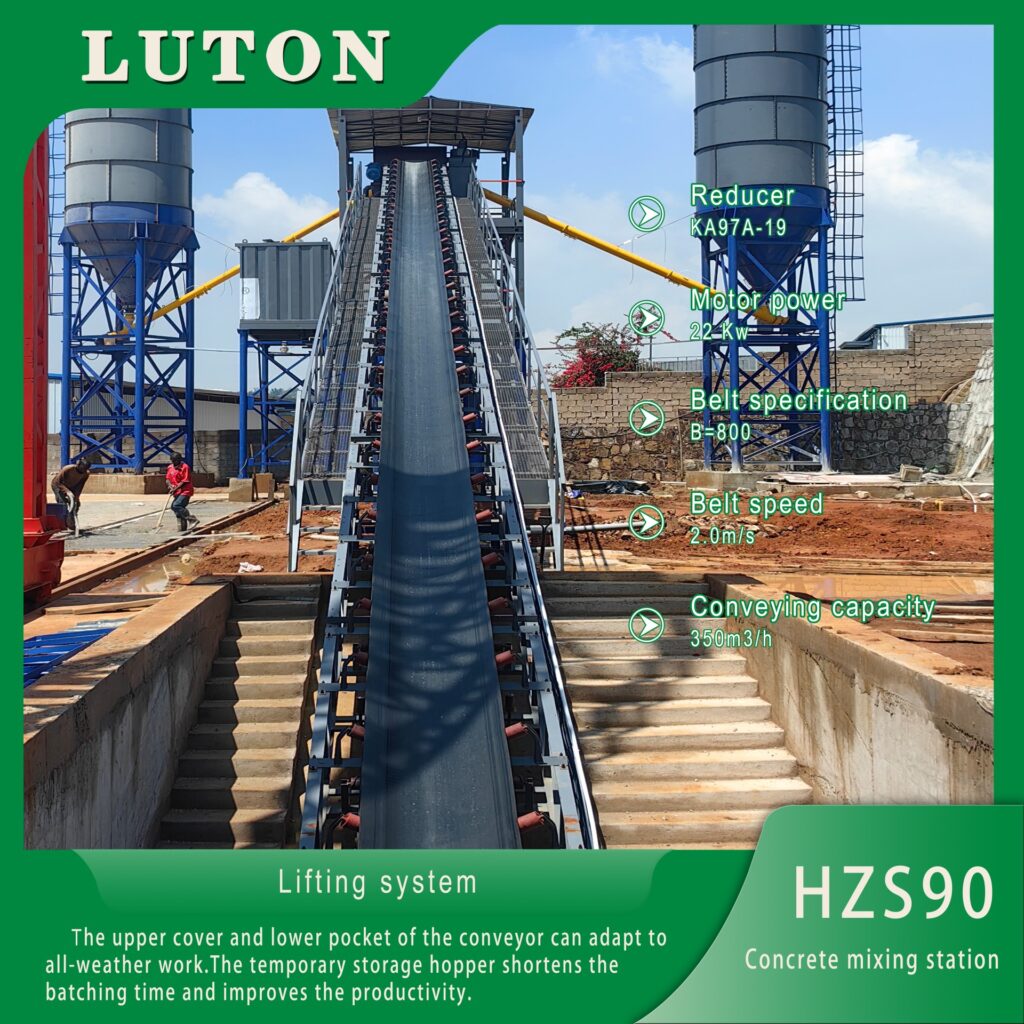

The aggregate feeding adopts a belt conveyor, which has a long service life and high work efficiency.

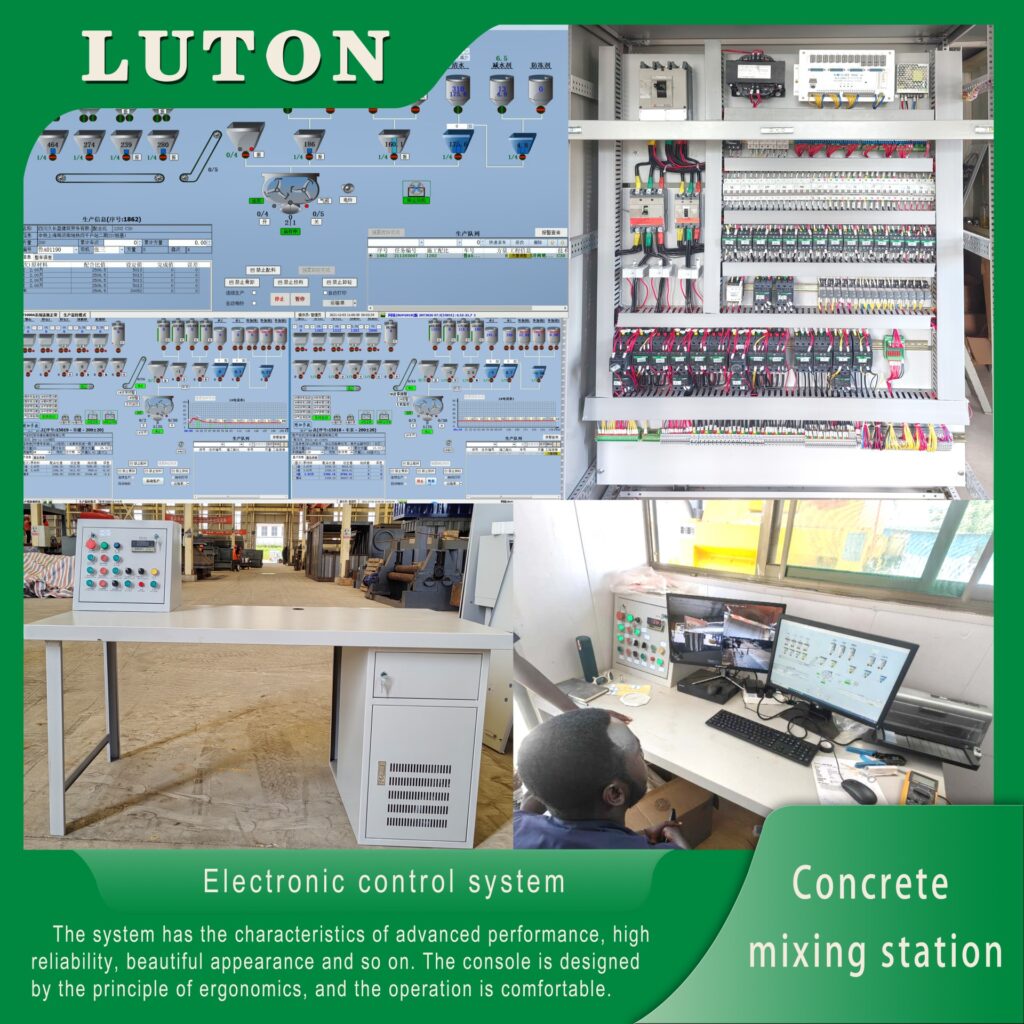

The main components of the electrical control system are all imported, with reliable performance, easy operation and use, printing function, and air conditioning.

[Product Features]

Short mixing time, good mixing uniformity, can provide you with high-quality concrete.

Electronic weighing is used for the measurement of various materials, which is accurate and reliable, and the measurement accuracy meets or exceeds the requirements of national standards.

Adopting advanced control technology, it has functions such as automatic adjustment, compensation, and alarm.

All use internationally advanced electrical and electronic components to ensure reliable operation of the equipment.

The mixing host adopts double horizontal axis forced mixing technology, manufacturing technology of high wear-resistant lining plates and blades, reasonable layout of mixing arms and blades, advanced lubrication design, making the mixing drum more durable.

Modular design makes maintenance, installation, and transfer of the mixing plant convenient and flexible, saving you expenses.

Various material conveying technologies and equipment with different methods can provide you with various choices that are suitable for your site requirements.

A safe and comfortable operating environment provides you with an environmentally friendly product.

1. Mixing system

2. Electric control system

3. Enhance the system

4. Aggregate temporary storage hopper

5. Aggregate weighing system

6. Cement weighing system

7. Fly ash weighing system

8. Water weighing system

9. Liquid additive weighing system

10. Pneumatic system

11. Dust removal system

12. Spiral conveyor

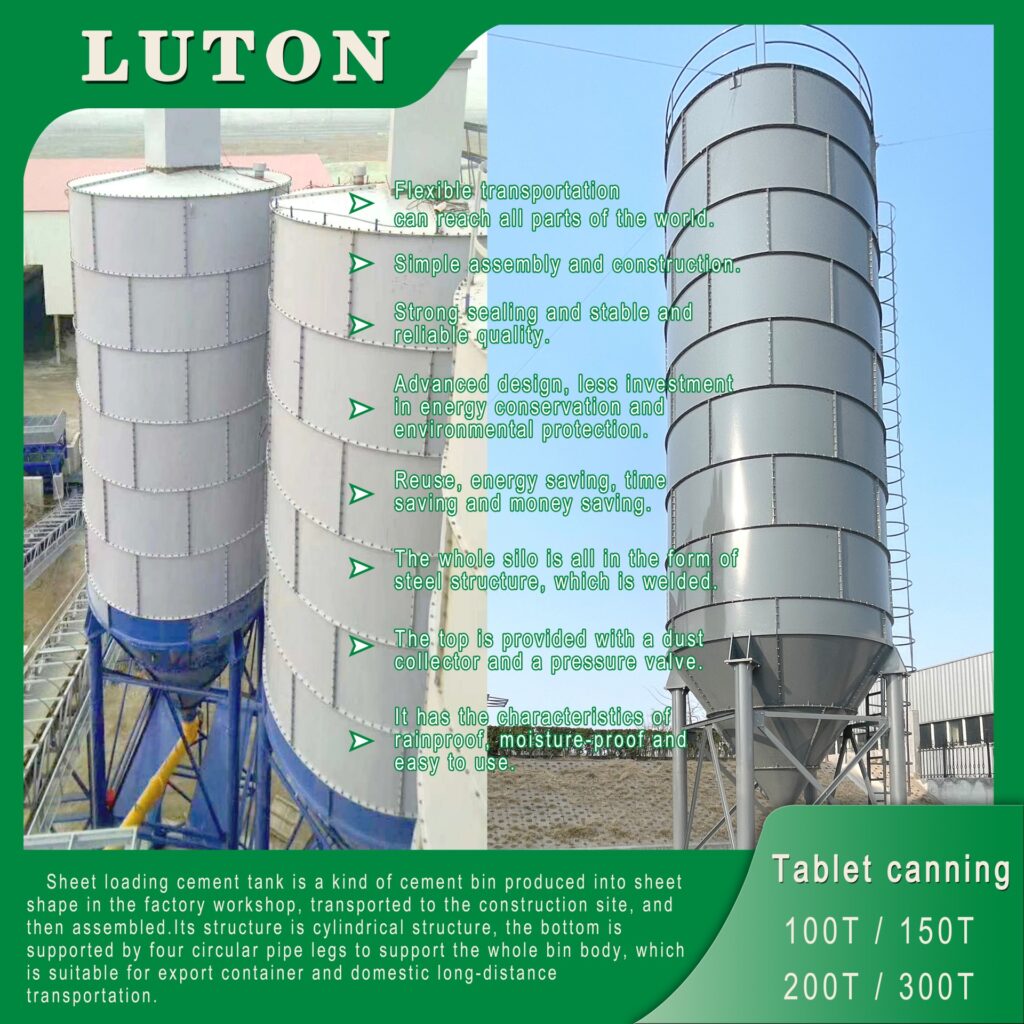

13. Cement silo

14. Control room

项 目 | 参 数 | |

型 号 | HZS90 | |

生产率 | 90m³/h | |

搅拌主机 | 形 式 | LTJS1500或仕高玛1500 |

出料容量 | 1500L | |

进料容量 | 2400L | |

电机功率 | 2 × 30kW | |

配料机 | 料仓容量 | 4 × 7m³ |

称量斗容量 | 2400L | |

皮带机功率 | 7.5kW | |

皮带机速度 | 1.6m/s | |

水及外 | 水 箱 | 无 |

外加剂箱 | 5m³ | |

称量装置计量范围 | 四种骨料秤 | 0~4500kg |

水 泥 秤 | 0~1000kg | |

粉煤灰秤 | 0~800kg | |

水 秤 | 0~500kg | |

液体外加剂秤 | 0~40kg | |

皮带输送机 | 带 宽 | 800mm |

带 速 | 2m/s | |

计量精度 | 沙石骨料 | ± 2% |

|

| |

水、液体外加剂 | ± 1% | |

水 泥 | ± 1% | |

粉 煤 灰 | ± 1% | |

粉状外加剂 | ± 1% | |

螺旋输送机 | 3 × LSY200 | |

粉 料 仓 | 3× 100t(或用户自定) | |

空 压 机 | 11kW | |

电控系统 | · 计算机全自动控制 · 动态彩显,中文字幕 · 按要求打印生产记录 | |

总 功 率 | 约191kW | |

总 质 量 | 约46t | |

卸料高度 | 3.8m | |

外形尺寸 | 45m × 20m× 12m | |